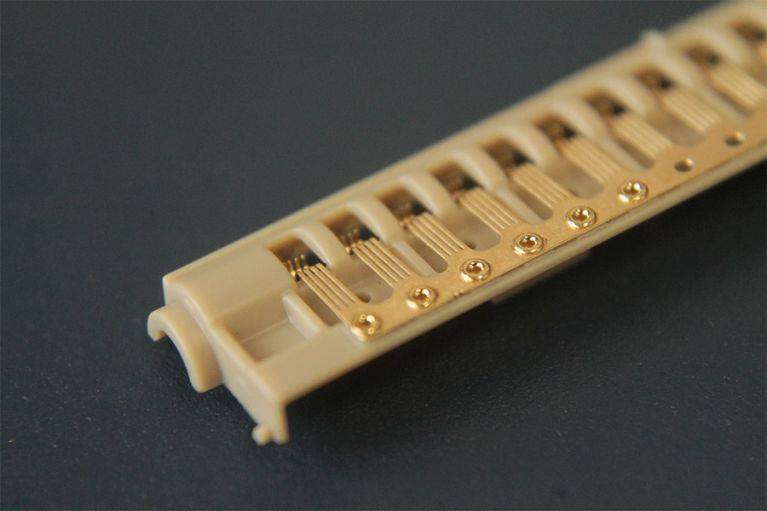

Electronic gold contacts

WHAT

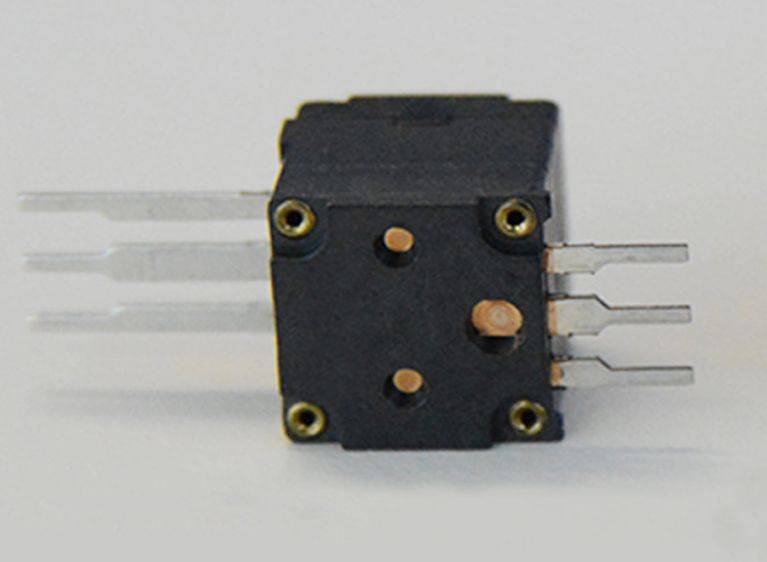

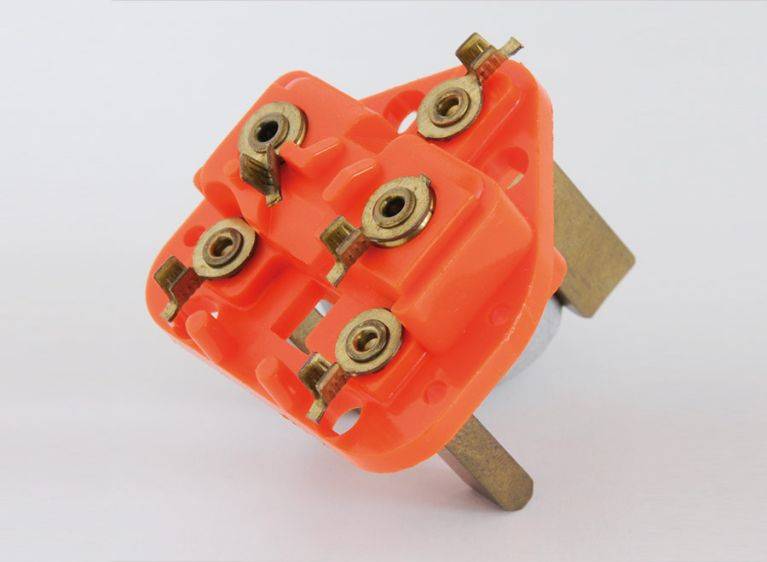

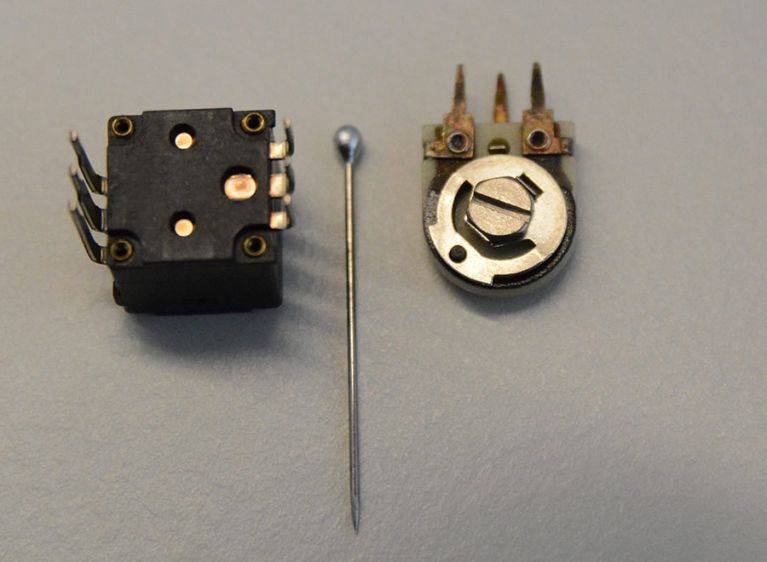

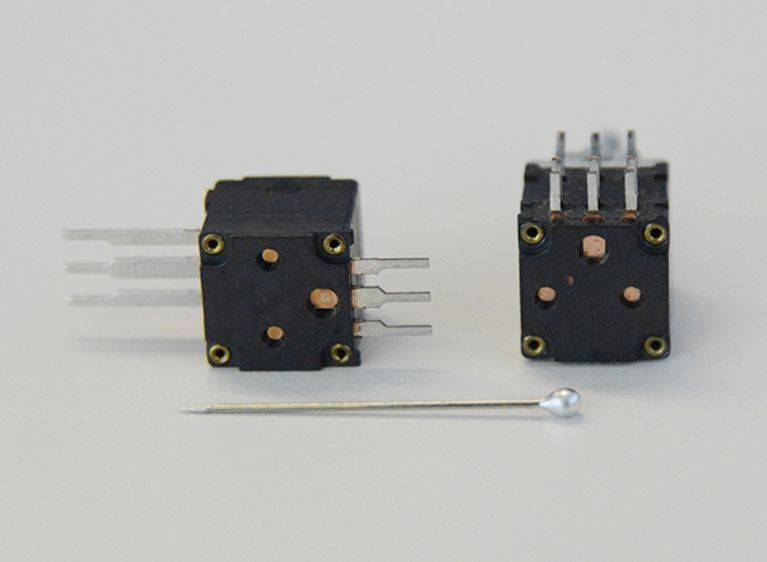

The task was the forming of highly conductive electrical gold contacts.

WHY

Meeting the quality requirements with the use of hand presses and the like is not possible. It is essential to guarantee a highly conductive, resistance-free contact connection for up to 25 connections per rail. The entire contact rail is unusable if there is only one inadequate connection.

HOW

By using perfect riveting tools and dies, precise riveting machines and the ability to precisely control the forming process, the components can be manufactured to the highest quality.

Facts & Figures

| Reference No. | BCHA1026 |

| Forming Process | Radial |

| Material | Gold-alloy |

| Geometry | Inner-Ø0.8mm Outer-Ø1.2mm |

| Shank type | Hollow |

| Rivet head geometry | Eyelet-flare |

| Forming Tool | Eyelet-flare with superfinish |

| Performance Data | Forming time: 1.2 sec. |

| Equipment | Manual feeding / positioning by special precision made fixture |

| Application Area | Electronic engineering, medical engineering |

| Devices | Radial riveting machine RN151 with Process Control HPP |

| Process Control | HPP-25 Process Control |

| User Benefits: Process | Reliable and stable process, quality-improvement (Scrap rate <0.01%) |

| User Benefits: Economic |

Production cost savings |

This project was realized by BalTec AG

For further questions or detailed information contact:

BalTec AG

Obermattstrasse 65

8330 Pfäffikon

Switzerland

Phone +41 (0)44 953 13 33

E-mail baltec(at)baltec.com