Articulating Roller Forming

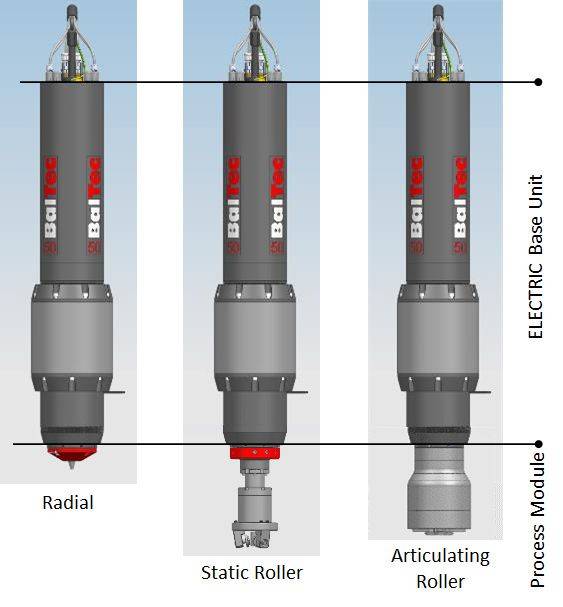

The new ELECTRIC EA30 is the world's first fully servo-driven articulating roller forming machine with three axis.

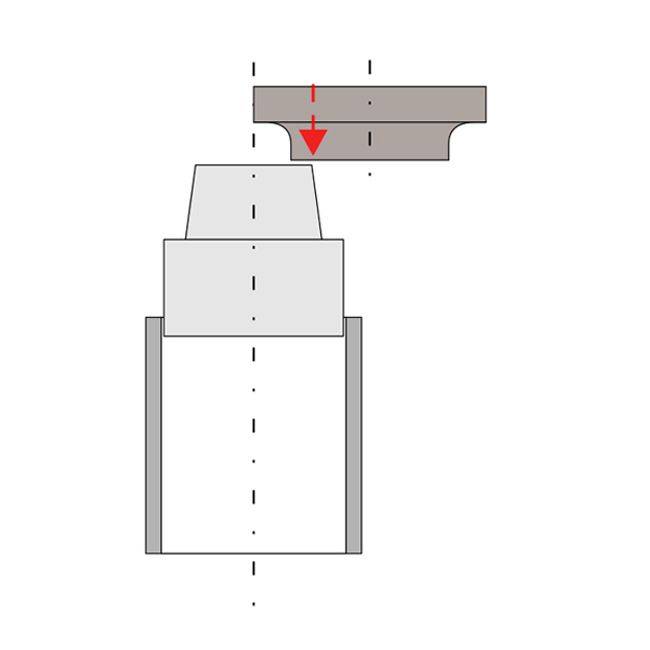

Thanks to its fully servo-driven process control, workpieces are formed with three axis, one in vertical motion downwards, one in a rotary motion, and one in an articulating (in-out) motion of the rollers. The process control software is individually programmable, allowing the machine to perform 3D profiles.

What makes the ELECTRIC EA30 so unique is the servo-controlled articulating motion, which delivers significantly higher precision and control than conventional solutions that require manual adjustment of a mechanical stop.

Last but not least, an attractive feature of the ELECTRIC EA30 is its slim design, as all three servo motors are aligned within the unit. Therefore the EA30 is well suited for integration into automated production lines with limited space or as part of a stand-alone work cell where frequent changeover of nests and programs may be necessary.

Innovation of the year: the first fully servo-controlled articulating roller forming machine.

Essential Features

Drive Concept

The worldwide first articulating roller forming device with three fully servo-controlled axis offers fully programmable, 3D motion profiles!

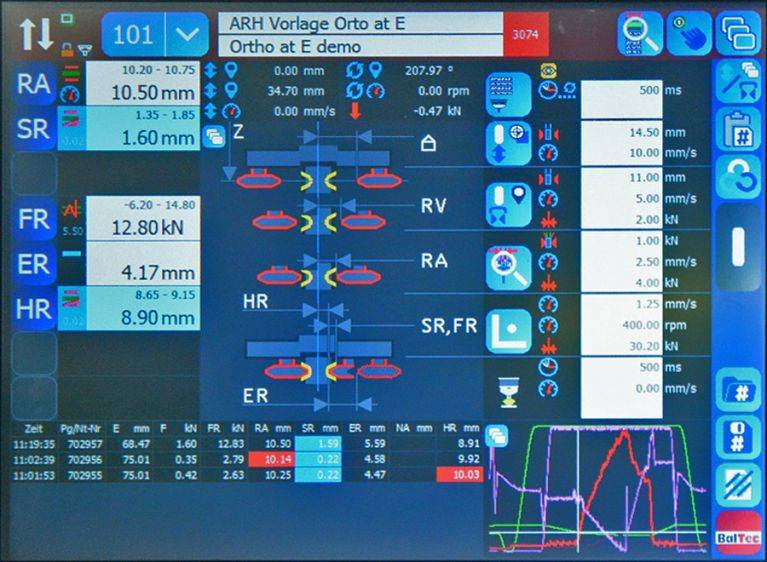

Process Control

Servo-controlled forming in radial direction, including monitoring of process data such as force/distance curve. The enhanced HPPi PC Software offers full process traceability and meets Industry 4.0 requirements.

Cycle Time

The EA30 is able to form multiple profiles in one machine cycle and thus increases throughput requiring less part handling which in turn saves valuable production time.

High Precision

Servo-controlled forming for much higher precision than mechanical hard stop and reduced reject rates.

Easy Integration

High compact form factor which can easily be integrated in fully automated production lines.

ARTICULATING ROLLER FORMING

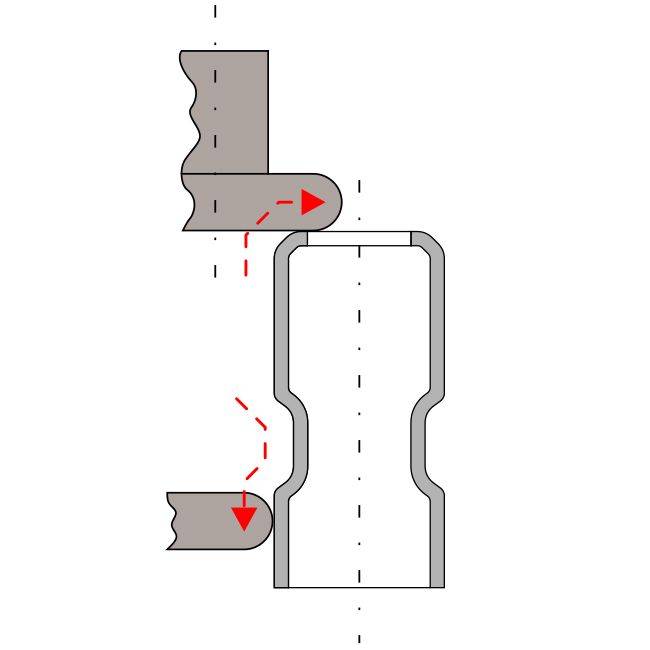

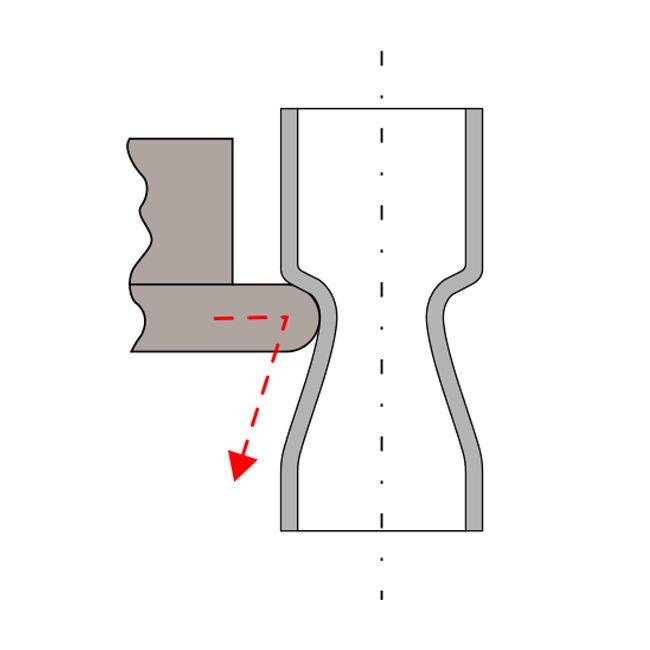

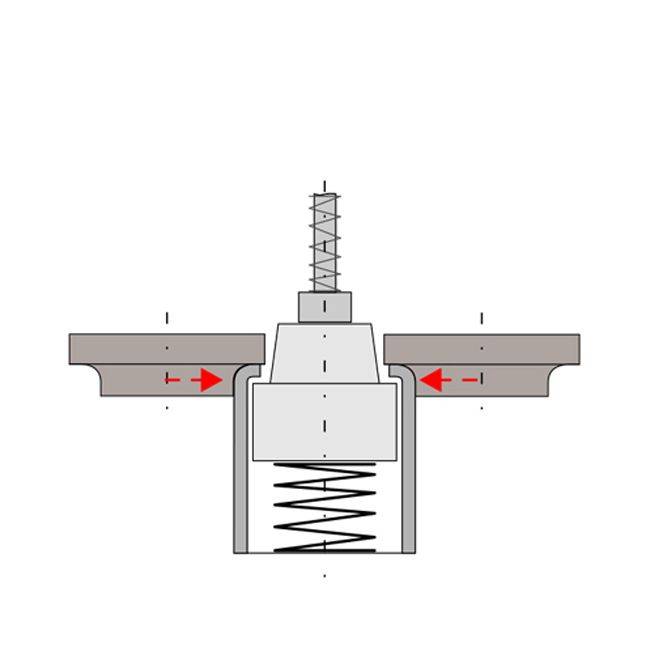

Articulating roller forming of a groove in a metal tube is a process technology that is very frequently used for fastening bearings in hollow parts or when it is necessary to form around an obstacle.

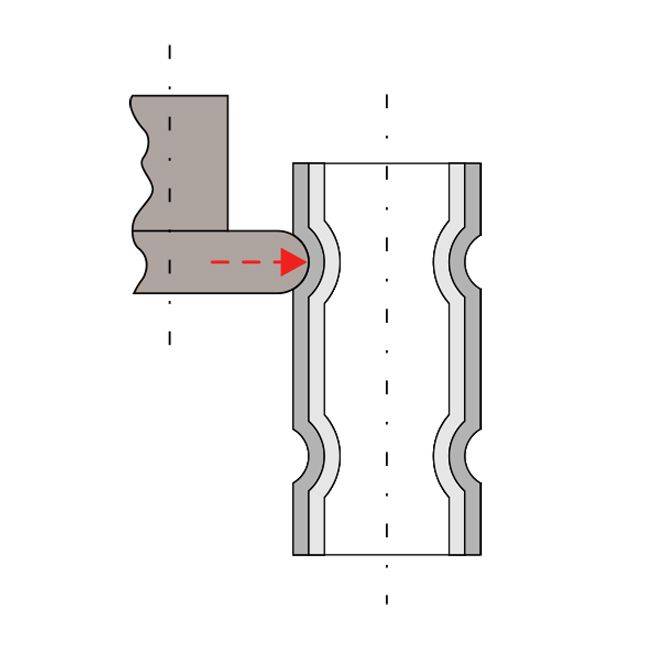

3D FORMING

The new ELECTRIC EA30 roller forming machine with three fully servo-controlled axis is capable of forming tapered profiles. This process is prevalent in sensor technology or for parts used in automotive, aerospace, and industrial manufacturing.

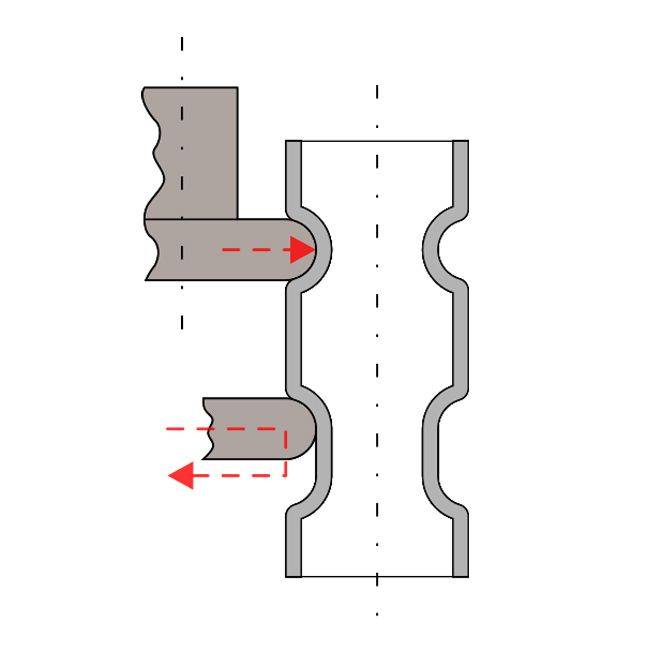

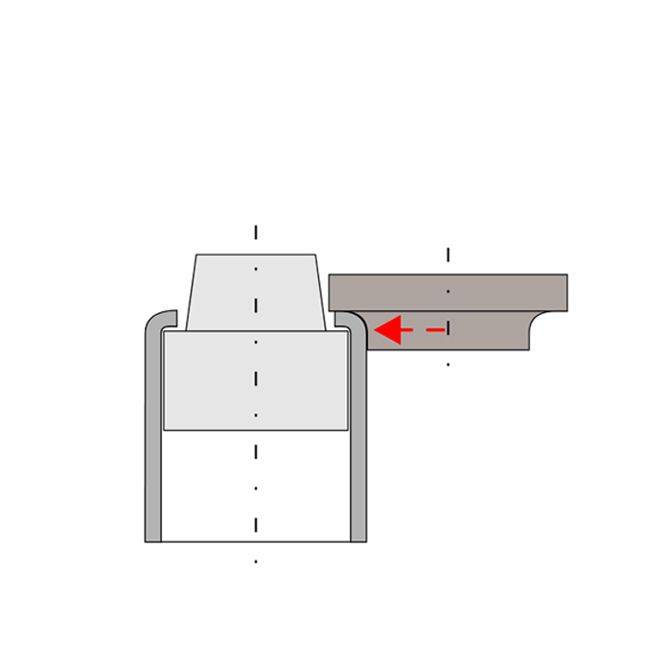

CRIMPING

The radially programmable articulating rolls can crimp from three sides with a force of up to max. 10 kN per roll. Thus, the new EA30 of the ELECTRIC line fulfills another popular joining method.

Efficiency & Advantages

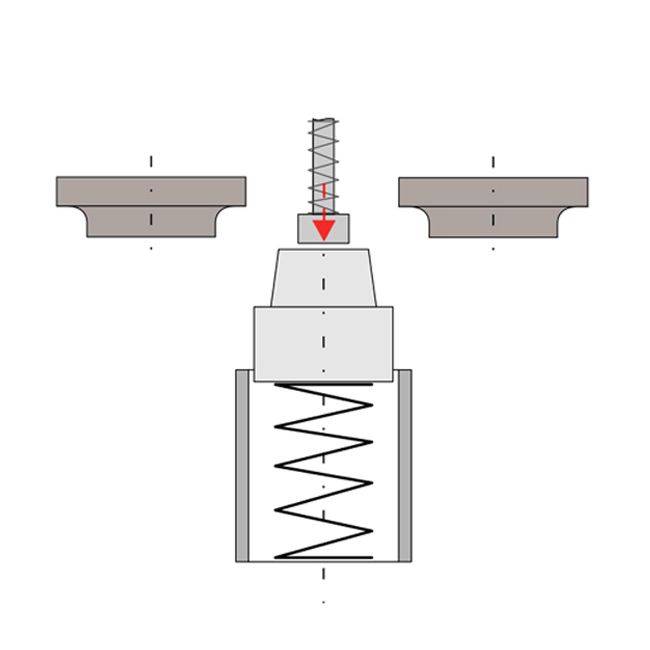

- Setup – In one setup, form several features. No setup change necessary.

- High Flexibility – Also a perfect fit for R&D laboratories and smaller production batches. Much easier and less costly to integrate in fully automated production lines due to the compact form factor.

- Cycle Time: Define & execute various crimp features (vertically and radially) within one program! No setup change or part transfer required.

- All 3 axis fully servo-driven, allow quick adjustments of process parameters without the need to move hard stops.

- Roll forming requires lower forces than crimping. It, therefore, puts less stress on parts and or on surface coatings and consumes less energy.

- Form a variety of geometries with the same roller wheels due to the capability of 3D forming.

- Save space & money: One EA30 executes operations of multiple stations.

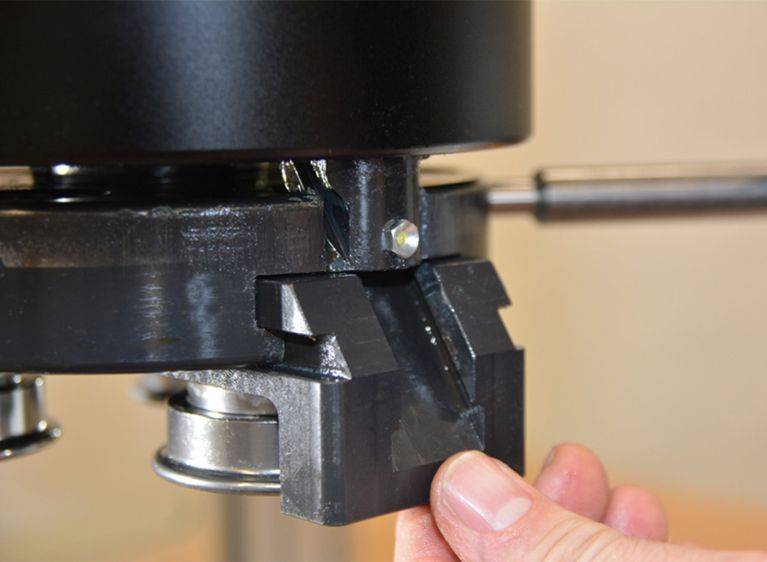

- Change Over: Quick change of forming tools.

- Expansion on BalTec's well-established ELECTRIC base unit with standardized HMI & easy integration into a control system.

- Modular concept with different process modules.

- Easy and fast interchange of different roller wheels.

Articulating Roller Head

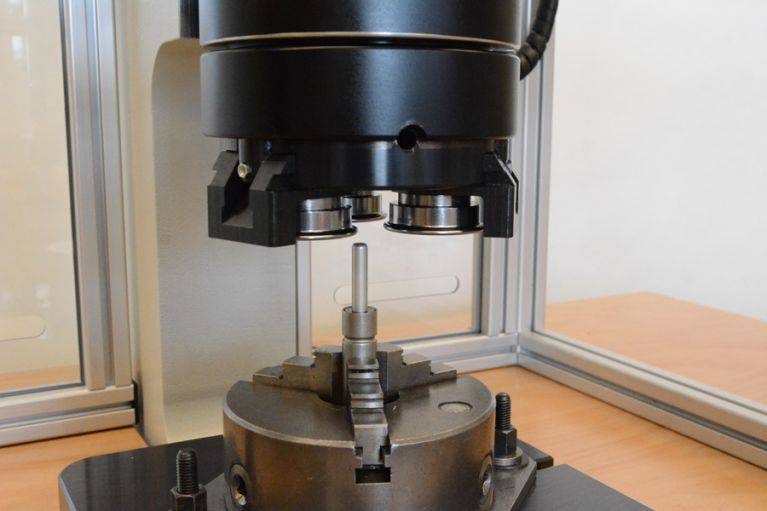

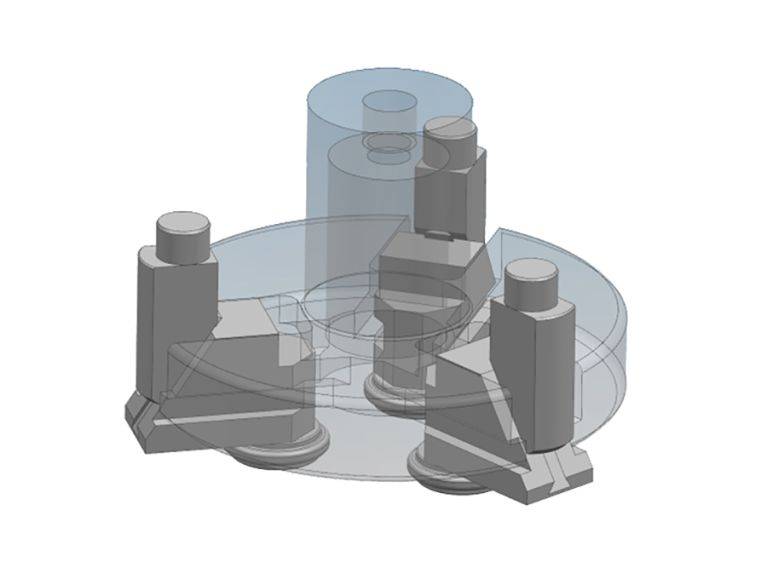

The articulating roller forming head differs significantly from the conventional BalTec roller heads.

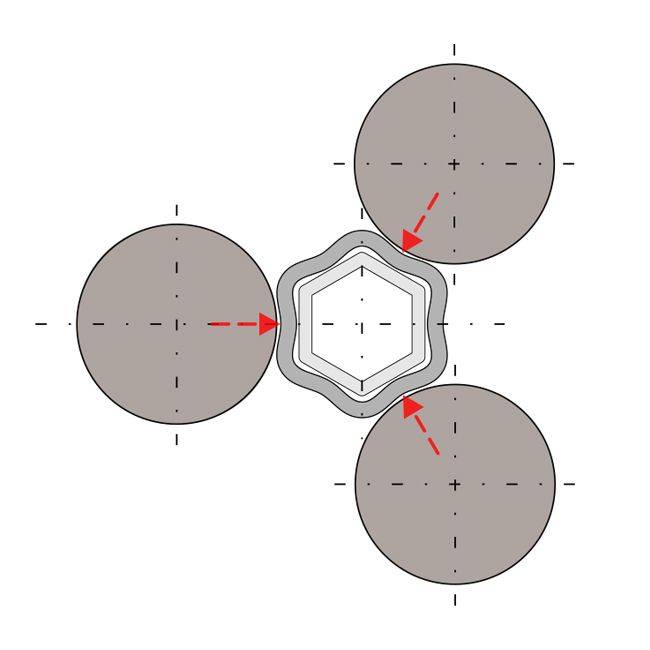

The articulating roller heads of the new ELECTRIC are always equipped with three roller wheels. The EA30 forms the workpieces from 360° with a maximum force of up to 30 kN. The force applied is distributed evenly over the three rollers, so a maximum of 10 kN is available per roller. These three roller wheels form a variety of profiles with just one roller head.

Compared to this, any static pneumatic or hydraulic machine is equipped with an individual roller forming head where the rolls are defined by the customer's specifications that need to be developed for one single profile.

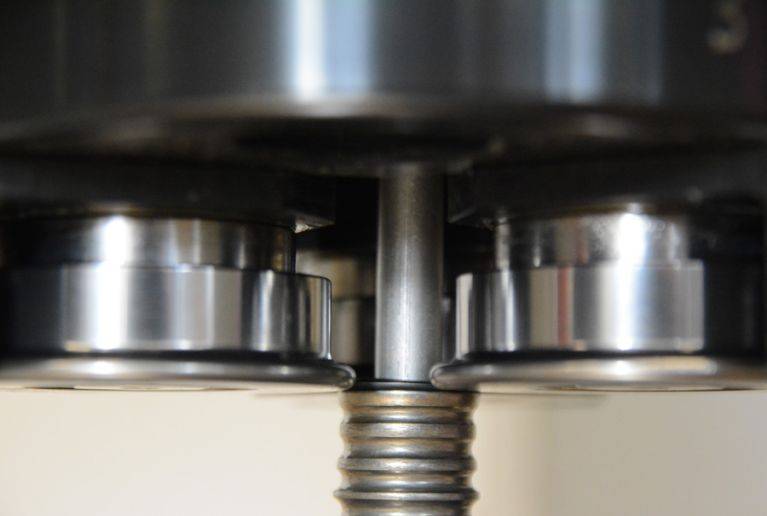

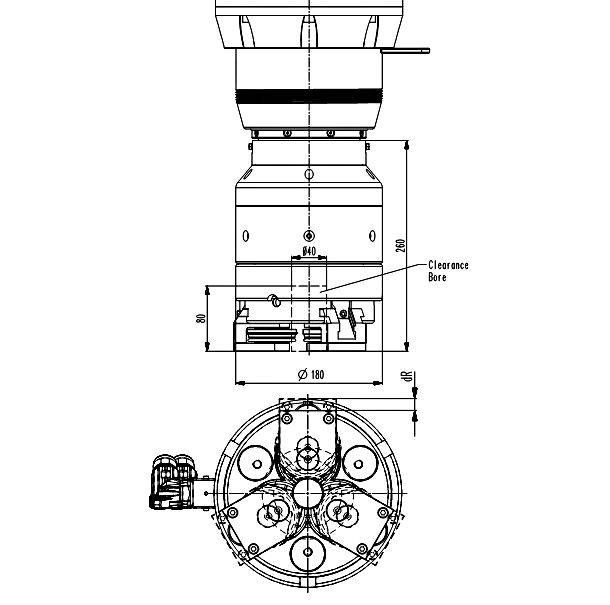

A bottom view of the process module with the radially articulated rollers

Technical Specifications

| Radial travel | 10 mm |

| Max radial in/outward movement speed | 10 mm/s |

| Forming speed | 0-10 mm/s radial |

| Max. radial force per slide / all slides | 10kN / 30kN |

| Max. axial force | 30 kN |

| Part Ø to Roll form (with diff. rollers & slides) | PØ5 – Ø25 – Ø75* mm |

| Part height – internal clearance (Part Ø < 40mm) | 80 mm |

| Part height – internal clearance (Part Ø > 40mm) | 20 mm |

* Larger diameter possible on request

Rollers can easily be interchanged – for different forming geometries and diameters, in sets of three rollers